MEMS Fabrication

Back to In-Situ Electron Microscopy for Nanomaterial Synthesis

Contact: Federico PANCIERA

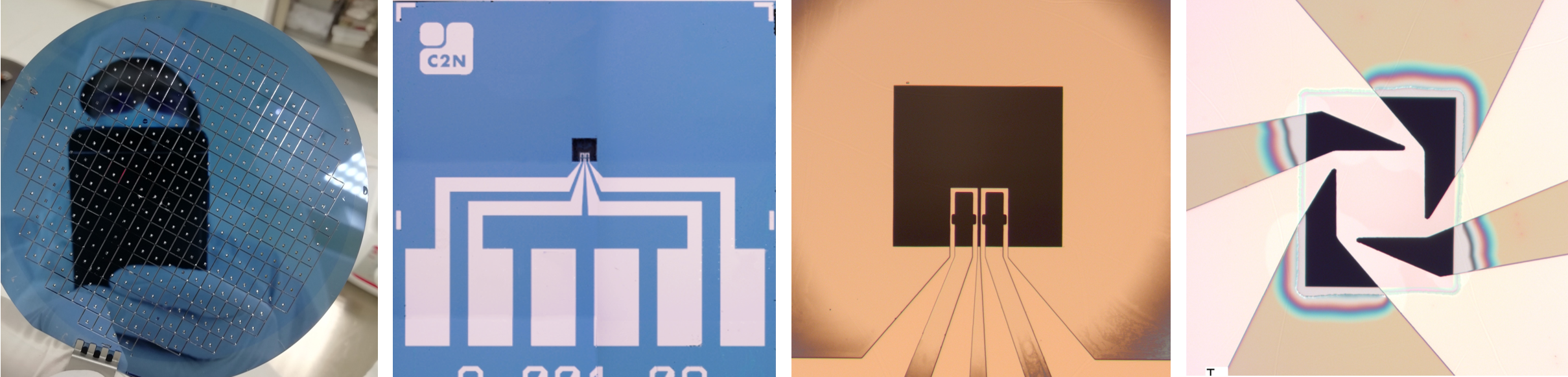

With the extensive capabilities of the C2N cleanroom facility (PIMENT), we fabricate custom MEMS-based substrates for in-situ epitaxial growth.

Leveraging wafer-scale fabrication, we produce precisely engineered samples featuring a variety of designs, including suspended membranes and cantilevers. Through an iterative process of finite element simulations, fabrication, and advanced characterization, we have optimized several designs with tailored properties such as exceptionally high thermal and mechanical stability and temperature uniformity across the membrane surface. These substrates have been instrumental in a wide range of studies, including nanowire growth, III-V thin film integration on silicon, Stranski-Krastanov (SK) quantum dot fabrication, and droplet epitaxy. Additionally, membranes can be patterned to facilitate the investigation of selected area growth, broadening their application potential. This integrated approach ensures the reliability and versatility of our MEMS-based substrates, enabling cutting-edge research in nanomaterials and device fabrication.

Figure caption. Left to right: 100 mm wafer after processing into MEMS chips; Single chip showing electrical contacts, middle hole for electron transmission and suspended heating substrates; Detail of a Cantiliver heating substrate; Detail of a membrane heating substrate..

Our MEMS fabrication activities play a crucial role in supporting several high-impact projects, including:

ANR ELEPHANT: Focused on controlling the crystal phase on GaAs nanowire with an electric field.

ANR SOLITUBE: Dedicated to exploring the growth of single wall carbon nanotubes under electric field.

ANR NUAGES: Aiming to improve the epitaxy of III-V materials on silicon.